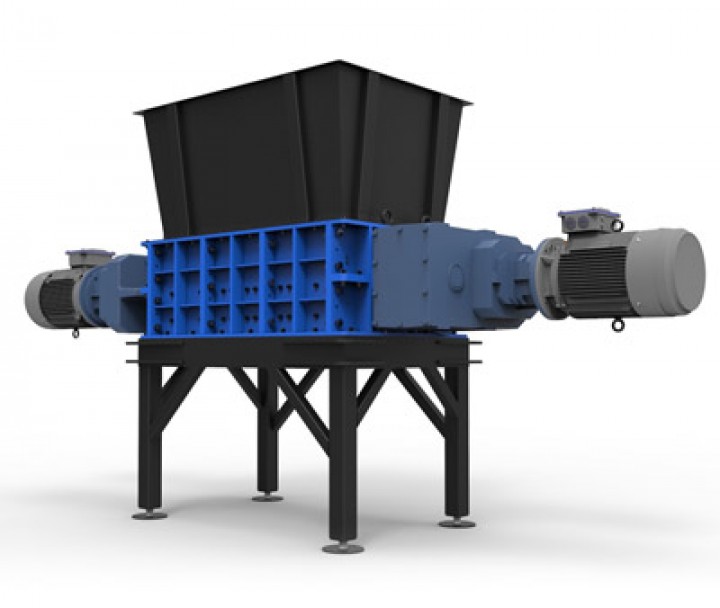

Shredding machines

In the broadly understood industry, shredding machines play a significant role. Their participation in recycling processes is invaluable. However, it is worth knowing what exactly are the characteristics of individual shredding machines and how and where they can be used. Increasing efficiency as well as improving some processes related to broadly understood processing is one of the most important tasks that is carried out thanks to properly matched shredding machines. However, we would like to bring you a little closer to the advantages of selected machines and point to other, perhaps new, solutions that you are able to implement with the help of a properly selected shredding machine.

What are shredding machines?

Before we begin by pointing out in which industries and why shredding machines are invaluable and how they can be used, it is worth explaining what exactly they are characterized by. First of all, all the machines we offer are entirely manufactured in Poland. We have trusted associates who make various machines for us and thanks to this, we have constant access to information on what and how many machines we are able to obtain and how long the waiting time will be. What's more, the production of our shredding machines in Poland is also a guarantee that there will be no problem with access to selected parts of a specific machine - e.g. in a situation where it would be necessary to modernize a selected model.

All our shredding machines are made of the highest quality materials, which guarantees their durability. We also attach great importance to the way they are made - we want the devices offered by our company to serve our customers as long as possible. So far, our devices have been used (and still are) not only in production plants in Poland, but they are also appreciated on western markets: in Germany, Austria and Switzerland. Our offer includes several types of shredding machines - both one-roller and two-roller. Depending on your needs, we recommend those that will definitely work best in your companies.

Shredding machines - otherwise shredders

Surely many people have come across another, equally popular term used in the context of shredding machines, which is shredder. This is a popular, abbreviated name for such machines, entirely referring to what exactly we can do with them. Shredders first shred large-sized products - including pallets or e.g. tea leaves. Thanks to this, their use is really very versatile.

Application of shredding machines

Shredding machines, as we have already written, are used in various industries such as:

• carpentry,

• recycling,

• pharmaceutical,

• paper,

• metallurgy,

• from synthetic materials.

The use of a shredding machine in a given industry is primarily dependent on its model and on what parameters it will be characterized by. In our offer you will find machines that are ideal for the above-mentioned industries.

Shredding machines - use in the carpentry industry

The production of furniture as well as its components requires the use of shredding machines. With their help, we are primarily able to reuse individual raw materials. Shredding of used elements for reuse is currently the most common use of shredders. However, it cannot be said that this is their only application. The disposal of waste that is no longer suitable for reuse also requires the use of shredding machines. Thanks to this, waste can be disposed of in an appropriate manner and in accordance with the highest safety standards. In addition, shredding machines greatly facilitate the process of both shredding individual components for reuse and preparing them for disposal. Thanks to this, carpentry workshops can work faster but also become more efficient. The ability to set the appropriate parameters of the shredding machine allows for a perfect adjustment of its work program to the needs of our company.

The importance of grinding machines in the pharmaceutical industry

Another, equally popular application of grinding machines is their use in the pharmaceutical industry. The substances from which medicines are made - including herbal ones - require prior processing. It is often associated with the proper preparation of raw materials for the further process of drug production. Shredding of raw materials is possible with the use of properly selected shredders. Our experts are able to choose not only the best model of such a machine that will be perfect for pharmaceutical plants, but also indicate what parameters should be paid special attention to. The order of the shredding machine is carried out in an individual way - in accordance with the customer's requirements. Crushing machines used in the pharmaceutical industry have parameters similar to those dedicated to the tobacco or tea industry. However, it cannot be said that these are shredding machines with identical parameters.

Shredder machines - application in the plastics industry

Our offer also includes machines that are perfect for the plastics industry. They are used primarily for grinding various raw materials made of plastic: foil, bubble wrap or other similar materials. Their importance is of great importance in the plastics industry, because they allow, above all, to reuse them. Plastic decomposes for a very long time, and in addition - it is extremely harmful to the environment. For this reason, more and more industrial plants related to plastics use shredding machines in their operations. They improve the work of plants, and also allow for a significant reduction in the emission of waste that is extremely harmful to the environment. Nowadays, we meet more and more often with plastic containers - bottles, packaging or foils that are made of recycled materials.

It is also worth noting that shredding machines used in the plastics industry also allow for the safe preparation of some raw materials for disposal. We are not always able to reuse plastic to create a new packaging. Effective fragmentation of it and then preparation for disposal and placement in an appropriate container for this type of waste is also possible thanks to shredding machines.

Paper and herbal industry

In our offer you will also find machines for shredding paper and herbs. Due to the type of raw materials subjected to grinding, these types of machines have slightly different parameters than those used for grinding wood or MDF boards. However, it is worth noting that they are distinguished above all by durability, speed of operation and the ability to set the most appropriate parameters. What's more, on an individual request, we are able to order a shredding machine that will meet the requirements of our customers in every aspect, even the smallest. The machine used for grinding herb or tea leaves is, first of all, very small, fully electric and its total power is 0.55 kW. It is equipped with a convenient switch that allows you to fully regulate the operation of this type of device.

Why is it worth trusting us?

Our devices are distinguished primarily by the fact that they can be used in various industries. The multitude of functions as well as the best technical parameters of our shredding machines allow them to be used in many industrial plants. In addition, we would like to emphasize that each order is priced individually - this is primarily due to the possibility of choosing the right type of shredding machine and the fact that it can be equipped with various technical parameters. In our work, we focus primarily on meeting the expectations of our customers and offering them solutions that will satisfy them in every way. We believe that only with such an approach, we are able to ensure 100% satisfaction of our contractors.

We take care of every, even the smallest detail related to the execution of the order: from the selection of the machine model, through matching its parameters to the customer's expectations, and ending with its delivery. The purchase of machines in our company is possible in many ways - including in the form of installments or leasing. Depending on your decision regarding the form of purchase, we support you in this process from the very beginning to its finalization. We also offer a very convenient installment system - prepared individually for each client.

We also encourage you to familiarize yourself with our offer, which is available on our website. Each machine is thoroughly described - from its parameters to power and the industry for which it is dedicated. If you have any questions, we are at your disposal - it doesn't matter if they concern the price, parameters or delivery time. We believe that together we will be able to find the best solutions and with our help you will implement the most modern solutions that will bring work in your companies to a new level.

biuro@zmprecyzja.pl

biuro@zmprecyzja.pl +48 603 680 035

+48 603 680 035